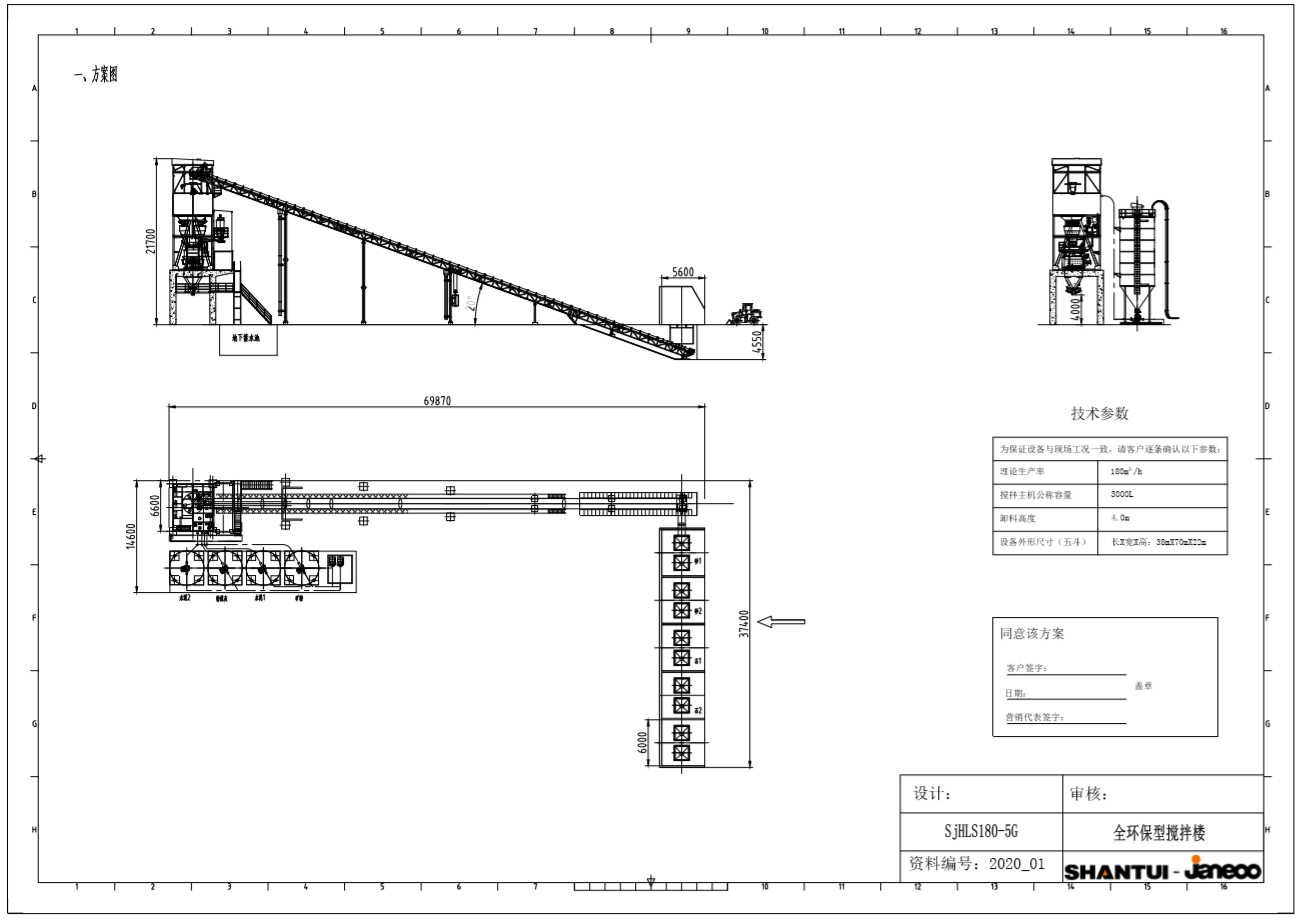

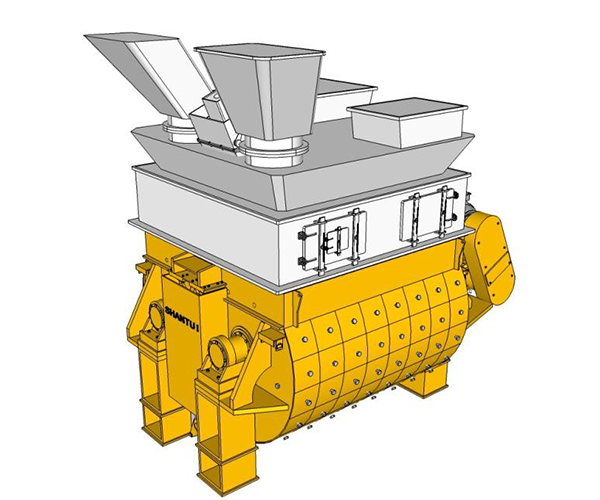

2.1 SjJS3000G mixer with high strength, high flow and explosive power

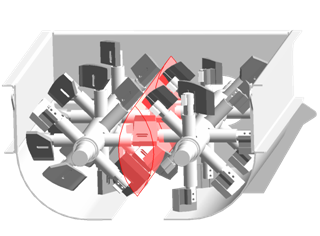

2.1 SjJS3000G mixer with high strength, high flow and explosive power  2.2 Unique cutting effect:

2.2 Unique cutting effect:  2.3 Unique air sealing device

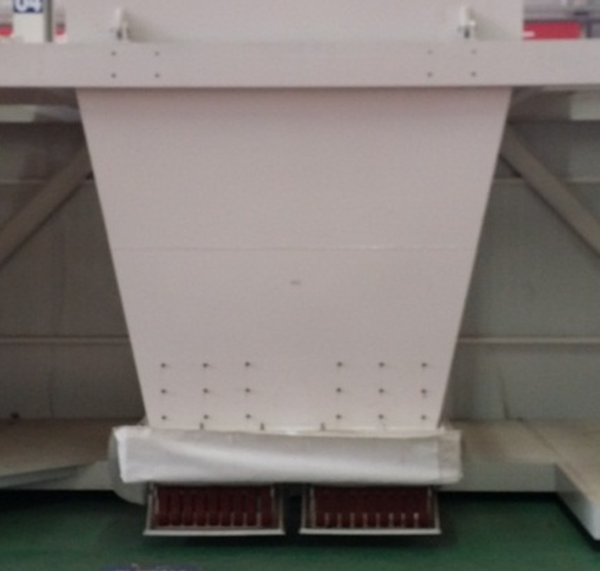

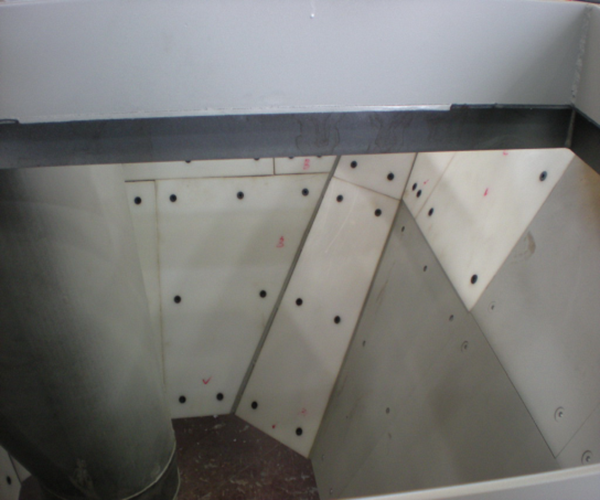

2.3 Unique air sealing device  3.1Unique 6m large-capacity finished product hopper:

3.1Unique 6m large-capacity finished product hopper:

4.1 Each weighing system has fine adjustment and compensation device, high weighing precision

4.1 Each weighing system has fine adjustment and compensation device, high weighing precision

5,Ready-mix feeding device

5,Ready-mix feeding device

Construction cases:

Construction cases:

Configuration

Configuration| 1、Main configuration | |||||

| Description | Item | Specification | Qty | Unit | Origin |

| 1 Aggregates batching machine (ground type) | Sand hoppers(ground type) | 50 m3 | 2 | set | Sensor:TOLEDO;Parts:SMC; Accuracy:±2%; |

| Stone hoppers(ground type) | 50 m3 | 2 | set | ||

| Weighing system | Max 3000kg | 4 | set | ||

| Sensor | SBT-2 | 12 | Pc. | ||

| Discharging gate | 4 | set | |||

| Flat conveying system | 400m3/h,B=1000mm | 1 | set | ||

| Driving system | 1 | set | |||

| Belt machine structure | 1 | set | |||

| Security device | 1 | set | |||

| 2 Aggregates conveying system | Inclined conveying system | 400m3/h ,B=1000mm | 1 | set | |

| Driving system | 1 | set | |||

| Belt machine structure | 1 | set | |||

| Whole Seal decoration | 1 | set | |||

| Security device | 1 | set | |||

| Chute washing device | 1 | set | |||

| Clean device | 1 | set | |||

| 3 Main building | Main steel structure | Discharging height 4m | 1 | set | Parts: SMC; Filter:WAM; |

| Main Filter | 44 m2 | 1 | set | ||

| Belt filter | 6 m2 | 1 | set | ||

| Main decoration | (50mm) | 1 | set | ||

| Concrete hopper | V:6 m3 | 1 | set | ||

| Monitoring device | 1 | set | |||

| Vibrator | MVE200-3 | 1 | set | ||

| Maintenance platform | 1 | set | |||

| Middle storage hopper | 1 | set | |||

| Weighing sensor | SBT-3 | 1 | Pc. | ||

| vibrator | MVE200-3 | 1 | set | ||

| Mixer | JS3000G(V:3 m3) | 1 | Pc. | ||

| Driving system | 2×55kW | 2 | set | ||

| Cylinder | CB-140B-450 | 2 | Pc. | ||

| Feeding device | 1 | set | |||

| Water pump | 1 | set | |||

| Monitoring device | 1 | set | |||

| Cement weighing system | Max 1800kg | 1 | Pc. | Sensor:TOLEDO;Valve:WAM; Accuracy:±1%; | |

| Weighing sensor | SBT-2 | 3 | Pc. | ||

| Valve | V1FS250 | 1 | Pc. | ||

| Vibrator | S30 | 1 | Pc. | ||

| Powder weighing system | Max 900kg | 1 | Pc. | ||

| Weighing sensor | SBT-2 | 3 | Pc. | ||

| Valve | V1FS250 | 1 | Pc. | ||

| Vibrator | S30 | 1 | Pc. | ||

| Mine weighing system | Max 500kg | 1 | Pc. | ||

| Weighing sensor | SBT-2 | 3 | Pc. | ||

| Valve | V1FS250 | 1 | Pc. | ||

| Vibrator | S30 | 1 | Pc. | ||

| Water weighing system | Max 800kg | 1 | Pc. | Sensor:TOLEDO;Accuracy:±1%; | |

| Weighing sensor | TSC-1000 | 3 | Pc. | ||

| Valve | 1 | Pc. | |||

| Additive weighing system | Max 100kg | 1 | Pc. | (Patent item)Sensor:TOLEDO; Accuracy:±1% | |

| Sensor | TSC-300 | 1 | Pc. | ||

| Valve | 1 | Pc. | |||

| Anti leaking device | 1 | set | |||

| 4 Water supply system | Valve | Each 1 | set | ||

| Pipes(Inter) | 1 | set | |||

| Water pump | 1 | Pc. | |||

| Pool and pipes(outer) | By customer | 1 | set | ||

| 5 Liquid additive system | Pipes | Each 1 | set | ||

| Pipes(Inter) | 2 | set | |||

| Additive tank and pipes(outer) | With pump,10T iron tank | 2 | set | ||

| 6 Pneumatic system | Air compressor | 15kW | 1 | Pc. | Parts:SMC;Dryer:SMC; |

| Storage tank | 1m3 +0.3m3 | 1 | set | ||

| Dryer | 1 | set | |||

| Pipe | 1 | set | |||

| Parts | 1 | set | |||

| 7 Control system | Control room | 1 | set | Main components:schneider; PLC:Siemens ; Monitor:SAMSUNG; | |

| Software | Bosure | 1 | set | ||

| Operating table | 1 | set | |||

| Control table | 1 | set | |||

| Monitor | 22” | 1 | Pc. | ||

| Printer | EPSON | 1 | Pc. | ||

| Air conditioner | 1.5 | 1 | Pc. | ||

| Computer | 1 | Pc. | |||

| Monitoring system | 4 cameras | 1 | set | ||

| Monitor | 22” | 1 | set | ||

| Light system | 1 | set | |||

| Communication | 4 cameras | 1 | set | ||

| 2、Optional | |||||

| 1 Cement silo | SC300 | V:300T(V:225m3,cement) | 5 | set | Cement 3set、powder 1set、mine powder 1set |

| SC100 | V:100T(V:73m3,cement) | 1 | set | Swelling additive | |

| Accessories | Filter, level meter, arch breaker etc... | 6 | set | Filter:Pulse back flush typeValve:WAM。 | |

| Platform on the top |

| 1 | set | Connection of all silos | |

| 2 Screw conveyor | For cement | φ323 | 3 | set | WAM |

| For powder | φ273 | 1 | set | WAM | |

| For mine powder | φ219 | 2 | set | WAM | |